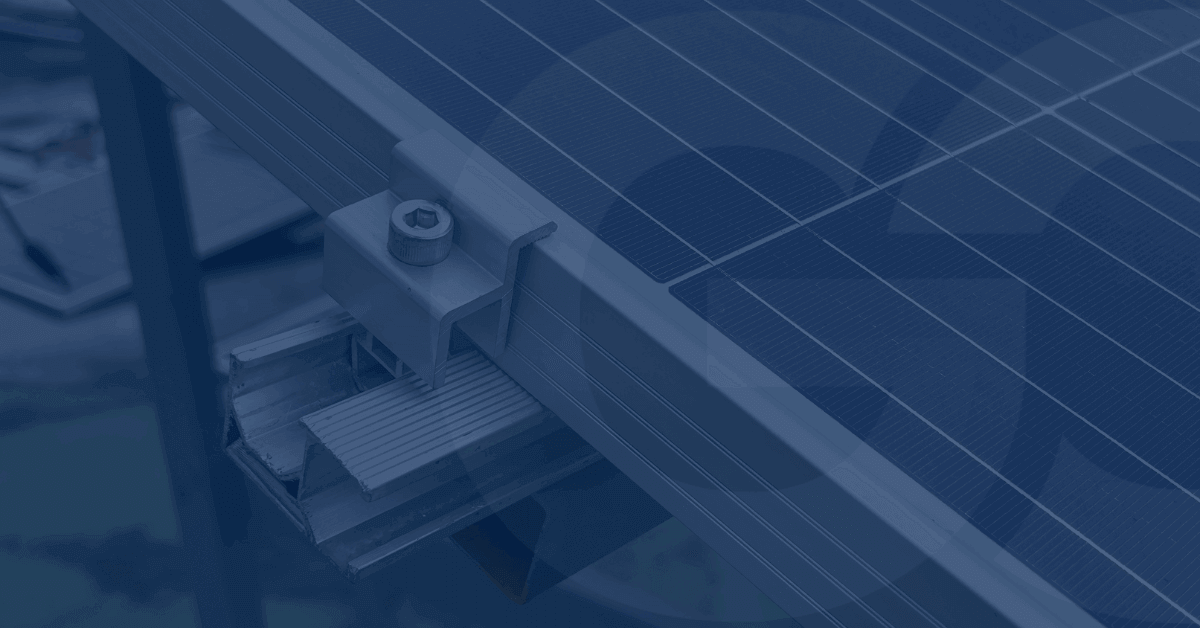

A photovoltaic (PV) system can only achieve its expected 25+ year service life if the engineering focus goes beyond the modules and inverters. It must also include the foundational principles of the mounting and racking system. Although often viewed as simple structural hardware, the mounting system is highly engineered. It protects the entire asset from mechanical failure and environmental degradation over decades of exposure.

This technical brief is for experienced solar installation professionals and system designers. It provides deeper insight into best practices for minimising long-term failure risks in racking systems. These practices include structural load management, smart material choices, water intrusion prevention, and mechanical stress control.

Structural Load Management

A mounting system’s primary function is to safely transfer dynamic loads such as wind uplift, vibration, and forces from thermal expansion and contraction from the PV array to the building’s underlying structure. The selection and proper installation of hardware specifically engineered to manage these forces are critical for system safety and longevity.

Key components designed to manage these dynamic loads include:

- Mounting Brackets (IBR, Corrugated, L-Brackets): As the primary anchor points, their design must account for both the specific roof profile and the underlying purlin structure to ensure a direct and secure load path, mitigating the risk of catastrophic failure from wind uplift.

- Mid-Clamps: By securing the inner edges of adjacent modules, these clamps unify individual components into a structurally monolithic array. This prevents the accumulation of localised stress on module frames during thermal cycling, a known contributor to cell damage over the asset’s lifetime.

- End-Clamps: These components secure the array perimeter, which is most vulnerable to aerodynamic forces. Engineers design them to resist the significantly higher wind uplift pressures at the array’s edges, preventing panel dislodging and cascading structural failure..

Hardware is usually specified with precise load ratings to guarantee performance under extreme conditions. For example, the Lumax Universal IBR Bracket is engineered with a shear strength of 5.3 kN and a tension strength of 9 kN. Specialised fasteners, such as wing-nut and bolt kits, are also rated to handle significant environmental stress. Some are engineered to withstand wind loads of up to 60 m/s. These specifications come from rigorous engineering analysis. They ensure the hardware can resist both predictable and extreme environmental conditions. The hardware materials themselves must provide inherent durability to match this resilience to external forces.

Hardware Specification & Material Science

The long-term performance of a mounting system depends on the material science of its components. The choice of metals and surface treatments determines the system’s ability to resist corrosion, UV degradation, and mechanical fatigue over a multi-decade lifespan.

| Material | Common Application Example(s) | Primary Engineering Benefit(s) |

| Anodised Aluminum | Rail Splices (AL 6005-T5), L-Brackets, Mid/End Clamps | Combines high strength with light weight for easier logistics and installation; provides excellent corrosion resistance. |

| Stainless Steel | Universal IBR Bracket (3CR12) | Offers superior strength to handle high shear and tension loads; provides exceptional weather and corrosion resistance, ideal for harsh climates. |

| Galvanized Steel | L-Brackets, Wing-Nut Bolts | Provides high strength and reliable corrosion resistance for structural fasteners and support components. |

Surface treatments are a critical element of this material strategy. Processes like anodising for aluminium and galvanising for steel create a protective outer layer on the metal. This layer is essential for guarding against long-term UV degradation and corrosion. For example, selecting 3CR12 stainless steel for the Universal IBR Bracket addresses the heightened corrosive threat in coastal or industrial environments. In contrast, anodised aluminium provides a lightweight and sufficient solution for less aggressive inland climates. This focus on material integrity is equally critical at the point where the system interfaces with the building structure.

Best Practices for Roof Integrity & Water Mitigation

Any penetration in a building’s roof, if not correctly managed, poses a risk of water damage, costly structural repairs, and voided building warranties. Best practices in mounting system design incorporate multiple layers of defence to ensure a durable, watertight seal at every attachment point.

The procedural steps for ensuring a watertight installation are built directly into the hardware design:

- Component Selection: The first step is selecting a bracket specifically designed for the target roof profile. Using a Corrugated bracket on a corrugated roof or an IBR bracket on an IBR profile ensures a proper fit that minimises gaps and facilitates a reliable seal.

- Gasket Integration: High-quality mounting brackets, such as the Corrugated and Universal IBR models, integrate EPDM or neoprene gaskets. During installation, the bracket compresses these durable, UV-stable rubber seals against the roof surface. This compression creates a primary waterproof barrier at the point of penetration.

- Fastener Specification: The fasteners themselves provide a critical secondary seal. Systems like the IBR Short Rail anchor utilise self-tapping or self-drilling screws that come with integrated EPDM/rubber washers. This washer seals the screw hole, preventing water from wicking down the fastener threads and into the roof structure.

By integrating these sealing solutions directly into the mounting hardware, designers and installers can effectively preserve roof integrity, maintain existing roof warranties, and deliver a system that will provide decades of reliable, maintenance-free service. This focus on integrity extends from the roof interface to the mechanical stability of the array structure itself.

Rail and Clamping Optimisation Strategies

Optimising the mechanical stability of the array structure is essential for protecting the PV modules from damaging stress and, consequently, maximising long-term energy yield. Localised stress on modules from an improperly designed or installed racking system can lead to degradation over time. The choice of rail architecture and clamping method is therefore a critical engineering decision.

Two distinct rail strategies address different project scales and logistical needs:

- Continuous Rail Systems using Internal Splices: For large arrays, internal rail splices made of anodised aluminium (AL6005-T5) join standard rail sections to form a single, continuous structural backbone. This approach is critical for ensuring superior alignment and even load distribution across long spans, which is essential for the stability of large-scale systems on commercial rooftops or ground mounts.

- Railless Systems using Short Rail Anchors: The IBR Short Rail system offers a cost-effective and material-efficient alternative. It creates compact anchor points directly on the roof. This approach is ideal for smaller residential or commercial installations. Furthermore, it simplifies logistics and allows for faster installation, while still providing a secure, waterproof anchor point.

The choice is a strategic trade-off. Continuous rails offer maximum structural integrity and better load distribution for large-scale projects. Railless systems, on the other hand, prioritise logistical efficiency and lower material costs for smaller, less complex installations.

Proper clamping is the final step in mitigating mechanical stress on the modules. Mid-Clamps maintain precise and uniform spacing between panels. This spacing is essential for preventing stress on the panel frames as the array expands and contracts with temperature changes. Adjustable End Clamps, typically ranging from 30–50 mm, provide a secure and customised fit for the panel’s specific frame thickness. This precise fit prevents movement or chatter caused by vibration or thermal cycling. It locks the module securely in place for the system’s entire service life.

Integrating Engineering Principles for System Longevity

The long-term success of a photovoltaic asset is fundamentally linked to the engineering principles embodied in its mounting system. For system designers and asset owners, adhering to these principles ensures asset bankability and mitigation of long-term operational risk. By specifying hardware with a thorough understanding of structural loads, material science, weatherproofing, and mechanical stability, installers can reduce common points of failure. This approach helps ensure safety, reliability, and optimal array performance over the system’s entire service life.

Key takeaways:

- Load Path Verification: Specify hardware not just for its physical fit, but also for verified load capacities that meet the project’s specific environmental conditions. This includes confirming ratings for shear (5.3 kN), tension (9 kN), and wind speed (60 m/s).

- Material-Environment Matching: The selection of materials (e.g., anodised aluminium vs. stainless steel) and the integration of robust weatherproofing (e.g., EPDM gaskets and washers) are paramount. This matching is the primary defence against premature system degradation from corrosion and water intrusion.

- System-Wide Mechanical Stability: The choice of rail architecture (continuous vs. railless) and the precise application of clamps are fundamental to preventing module stress. This attention to detail ensures the long-term structural integrity of the array and protects the power output of the modules themselves.

Register with us or log in to the Get Off Grid portal for our mounting solutions. Available at all our branches | Get Off Grid Randburg | Get Off Grid Centurion | Get Off Grid Cape Town | Get Off Grid Zambia

Like this article? Please share!

Disclaimer: The information provided in this article is intended for educational and informational purposes only. Every effort has been made to ensure accuracy. However, we advise that readers consult datasheets and installation manuals to verify information. For specific project requirements or additional guidance, please contact the Get Off Grid technical team.